System for registration of products TBKODA

- Production:

- КОДА (Ukraine)

TBKODA is a hardware and software system for registration and operational control of scale feeders and tank parks. It supports the unified enterprise system of storage and product movement accounting, check of the current status of weighing systems and level sensors for liquids and solids, detailed reports and charts creation.

The introduction of this product allows you to organize full control and security of storage processes and movement of products in the company, which enhances self-sufficiency of the system within the shortest time possible.

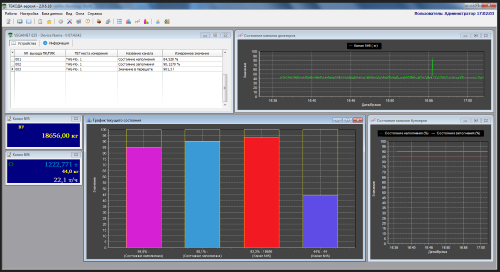

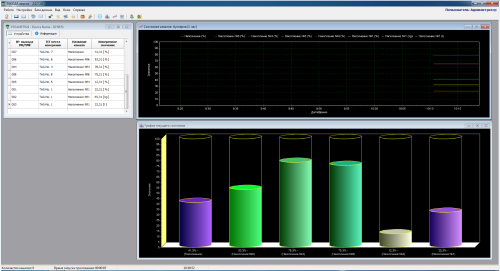

- Grafical data display

The system reads the information from the electronic scale feeders, hopper scales or sensor indicators on the interface RS-232C, RS-485, RS-422 or Ethernet. RS-232C offers the possibility to connect each computer with up to 10 weight tanks; RS-485 and RS-422 – with up to 32, depending on the network configuration; for level sensors the data collection is conducted through either specialized devices for signal compression or analog input devices. Connection of systems of different types and manufacturers are available.

On the PC screen the information about the status of each connected measurement channel is displayed in separate windows, in tabular form or with graphs and diagrams. Operators select the type of data display themselves.

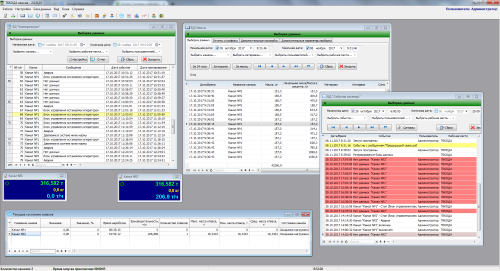

- Table data display

Measured data is stored in a secure database and is available through multi-user network access. This approach supports the connection of tanks with several PCs in the system and its network organization, which allows to view the system status from any PC, make adjustments and generate reports on any tank or group of tanks, as well as to organize remote workplaces of engineers and managers. Different access levels for configuration and information are provided.

Reports are formed in any cross-sectional data (by date / time, accounting node, tank, material, operator) in tabular or graphical form. The system calculates the dispenser capacity, the number of plummets, the average, maximum and minimum plummet weight, dispensers operating time, minimum, maximum and average expenditure in storage tanks.

The system automatically monitors the output values in each channel of preset values, signals them and stores the record in the system events database. Other important system events and the operator’s response to them are also recorded in the events database. For the purpose of diagnostics of the weight system there is a possibility to view the weight change graphs on each dispenser with high resolution.

The system works running Windows XP / 7/8 operating system. Special adapters are required to connect the RS-485 interface to a PC.

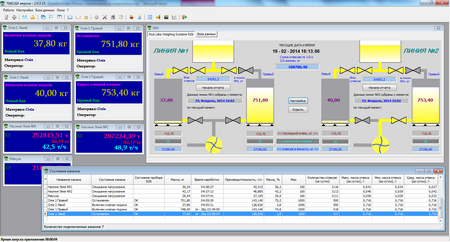

- Mnemo of the technological process

TBKODA software can be adapted to the technological scheme of the Customer, is equipped with a mnemo, which visually displays the status of all system components.

For processing industry there is a special "Login / yield" analysis mode, which allows to analyze the process of converting raw materials into the final product, considering the amount of side products and waste.

- Tanks park status display

For storage and product movement records special mode of the "floating" quantity measurement and display within specified time intervals and registration of weight values jumps are provided.

All system events are recorded in the system database with the opportunity of sending alarm messages and further analysis of the system operator’s response time.

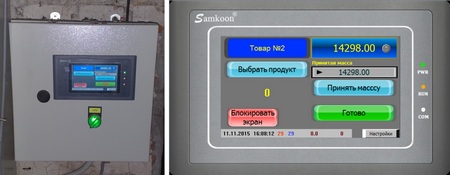

- Automatic control system

In addition to accounting and control functions, the system can be equipped with actuators for automated control of components dosing, mixing, crushing, etc. for the production of animal feed, building mixtures, concrete in accordance with the customer’s manufacturing techniques. The presence of the input components, accuracy and safety of mechanisms functioning, accuracy of the given recipe are automatically controlled, records of components and finished product expenditure are conducted.

Thus it is possible to create complex, multicomponent dispensing systems with integrated self-optimization processes, to work with numerous recipes, set the system configuration.

- Local control panel

In order to organize the workplaces of operators of dispensers and filling machines, the organization of local control sealed panels exists, and, being connected to the server system via Ethernet, it allows to manage the processes of receipt and shipment of products with immediate data synchronization. In case of connection failure the autonomous operation is possible.

Due to unified and extensible communication protocols, TBKODA can be connected to a variety of measurement channels which are applied in such containers as flow meters, temperature sensors, humidity sensors, pressure sensors. Flexible data mapping interface offers an opportunity to present the information in a way convenient both for operators and engineers.

See also:

- TASKODA software for weighbridges

- TVKODA software for wagon scales

- Software TPKODA