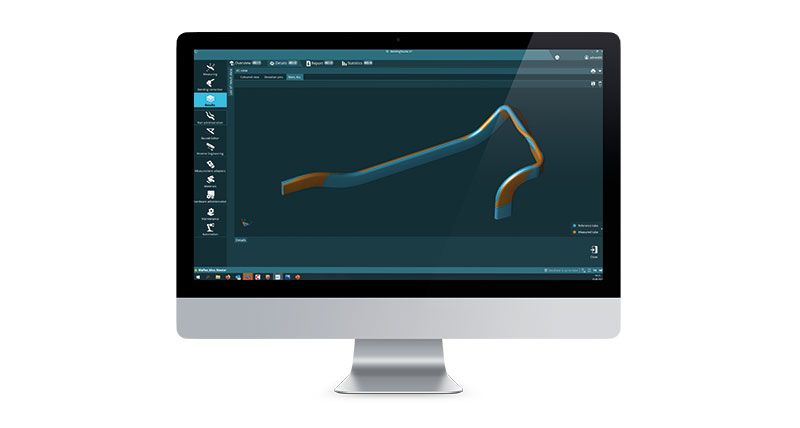

BendingStudio XT

Manufacturer:

- Hexagon MI ROMER (France)

BendingStudio XT connects all data and processes involved in the manufacturing of bent parts, from production planning and technology processes to manufacturing and quality control.

It is the only tool that meets these requirements and integrates them, with a focus on metrological processes. When used in conjunction with the TubeInspect or Absolute Arm systems, the BendingStudio XT software platform enables the creation of efficient, user-oriented solutions with a unique combination of speed, accuracy, and flexibility.

During the manufacturing of parts, different data is often required at various stages from the drawing to the verified product. This includes CAD data from design and bending process management programs, production process adjustment data, as well as test and inspection plans or measurement and analysis protocols for quality control. However, all these data are not always 100 percent compatible.

The BendingStudio XT platform allows for the unification of all parallel data sets related to a specific part, enabling manufacturers to control, quantify, visualize, and document all changes at different stages of the production process.

This platform is based on a simple, clearly structured processing concept, which includes numerous small tools that facilitate the work at various stages of bent part production.

The BendingStudio XT platform can be used for manual and automated inspection tasks as part of the TubeInspect measurement cell equipment, as well as with laser 3D scanners, tube sensors, and contact measurement probes in systems with the Absolute Arm measuring manipulator.

BendXtract Technology

The high performance of BendingStudio XT’s inspection procedures is based on BendXtract technology — a set of algorithms that allow the platform to automatically calculate precise bending geometry parameters without using labor-intensive precise scanning methods, transforming this data into easy-to-understand reports.

BendXtract uses the following algorithms: Free Scanning, Automatic Extraction, and Smart Results.