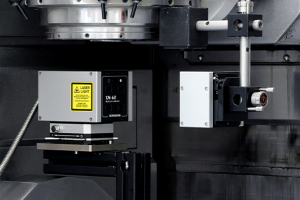

Interferometric system Renishaw ХL-80

Manufacturer:

- Renishaw (United Kingdom)

Renishaw XL-80 is an ideal technical solution for performing full calibration of any positioning system, measuring a wide range of geometric and dynamic characteristics. The system has a flexible modular structure, and the equipment is determined in accordance with specific metrological tasks and conditions of use.

The XL-80 laser unit is the basis of the measuring system. It is based on the use of a helium-neon (HeNe) laser tube producing a stabilized laser beam with a wavelength of 633 nm. The characteristics of each laser system XL-80 are verified on the basis of the standards of the National Physical Laboratory (NPL, UK). The XC-80 compensation unit, which is part of the system, constantly monitors the environment in the work area, receiving data from high-precision temperature, pressure and humidity sensors. Ultimately, the system achieves the highest accuracy - 0.5 μm / m in the operating temperature range of 0 ... 40 C.

The special software "Laser XL" fully controls the system preparation process and the measurements themselves. Analysis of the test results is carried out in accordance with international standards.

XL-80 allows you to control the parameters:

- accuracy of linear positioning (range 0 ... 80 m, 0.001 μm);

- angular displacement errors (axial range 0 ... 15 m, angular range (+ -) 175 mm / m (+ - 10 °), 0.1 μm / m resolution);

- straightness (axial range 0.1 ... 30 m, range of measured non-rectilinearity (+ -) 2.5 mm, resolution 0.01 / 0.1 μm);

- perpendicularity (permitted 0.01 μm / m);

- flatness (axial range 0 ... 15 m, range of measured deviations from flatness (+ -) 1.5 mm, resolution 0.01 μm);

- accuracy of rotational motion;

- relative bias over time;

- speed changes over time;

- acceleration changes over time.