HOMMEL-ETAMIC Opticline C300

- Production:

- JENOPTIK Industrial Metrology Germany (Germany)

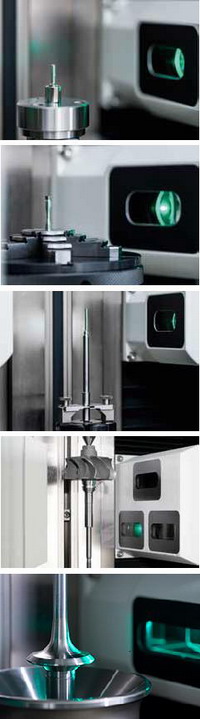

- HOMMEL-ETAMIC Opticline C305 / С310 / С314

This series of equipment offers a wide range of production solutions and includes three models of compact devices: Opticline C305, C310 and C314. They are suitable for measuring various objects: from the engine valves to the turbocharger shafts and short transmission shafts.

Using a system of high-resolution cameras it is easy to measure very small geometric elements of hardened shafts, obtained by turning. You can measure

parts with a total length of up to 300 mm, diameter from 0.2 mm to 140 mm and weight up to 10 kg.

System benefits:

- Full measurement in a few seconds;

- High resolution and accuracy;

- Low operating costs and virtually no wear;

- Automatic measurement operation;

- Enclosed housing with doors, optionally with motorized opening / closing drive;

- Intuitive and simple TURBO OPTIC software.

Specifications:

| Model | С305 | С310 | С314 |

| Limits of measurement | |||

| Diameter, mm: | 0,2 - 50 | 6 - 100 | 0,2 - 140 |

| Length*, mm: | 300 | 300 | 250 |

| Dimensions | |||

| Diameter, mm: | 150 | 150 | |

| Length*, mm: | 300 | 280 | |

| Gravity, N: | 100 | 100 | |

| Resolution | |||

| Diameter, mkm: | 0,1 | ||

| Length, mkm: | 0,1 | ||

| Rotation, °: | 0,018 | ||

| Accuracy / MPE ** | |||

| Diameter, mkm: | 2 + D [мм] / 100 | ||

| Length, mkm: | 5 + L [мм] / 100 | ||

| Repeatable *** | |||

| Diameter, mkm: | 0,5 | ||

| Length, mkm: | 3 | ||

| Speed | |||

| Measuring, mm/s: | Automatically optimized measurements: 10 - 80 |

||

| Measuring rotation, r/s: | 1 | ||

| Positioning, mm/s: | 200 | ||

| Positional rotation, r/s: | 1 | ||

| Measurement time: | Depends on the type and number of test characteristics usually 3 … 30 s |

||

| Dimensions of the measuring system [WxDxH], mm |

780 × 650 × 912 | ||

| Mass of the measuring system, N: | 1 400 | 1 450 | 1 550 |

| Interfaces of clamping devices | |||

| The lower Morse center: | МК 2 | ||

| The Morse cone: | МК 2 | ||

| Upper Center: | Manual, 20 mm | ||

| Source of power | |||

| Connection | AC-PH, N, PE | ||

| Voltage, V: | 230 / 115 | ||

| Frequency of mains, Hz: | 50 / 60 | ||

| Power consumption, kVA: | 1,5 | ||

* - Between the tips of the standard supply set. The length can be reduced depending on the clips.

** - Surface of polished part, ambient and object temperature 20°C ± 1°C.

Changes in ambient temperature of less than 0.5°C/h, in accordance with DIN EN ISO 10360 or VDI / VDE 2617.

Mechanical environmental conditions according to DIN EN 30721-3-3, class 3M2.

*** - With 25-times measurements on the surface of polished parts (according to VIM).

Examples of using the Opticline C300 system:

- Measurement of injection components;

- Measuring the valve piston;

- Measuring the injector needle;

- Measurement of turbocharger shaft;

- Measure motor valve with flexible, pneumatic clamp.

Accessories and clamping devices:

There is a wide choice of clamping devices, which guarantees reliable fastening of the shafts. Flexible holders MK 2 (with a cone of Morse 2) allow you to adapt the system to measure different objects.

Below are the most commonly used fasteners and clamping chucks:

- Various fastening tips;

- Variants of fastening inserts;

- Clamping chucks and face plates.

See also:

- HOMMEL-ETAMIC Opticline C203

- HOMMEL-ETAMIC Opticline C500

- HOMMEL-ETAMIC Opticline C800

- HOMMEL-ETAMIC Opticline C1000