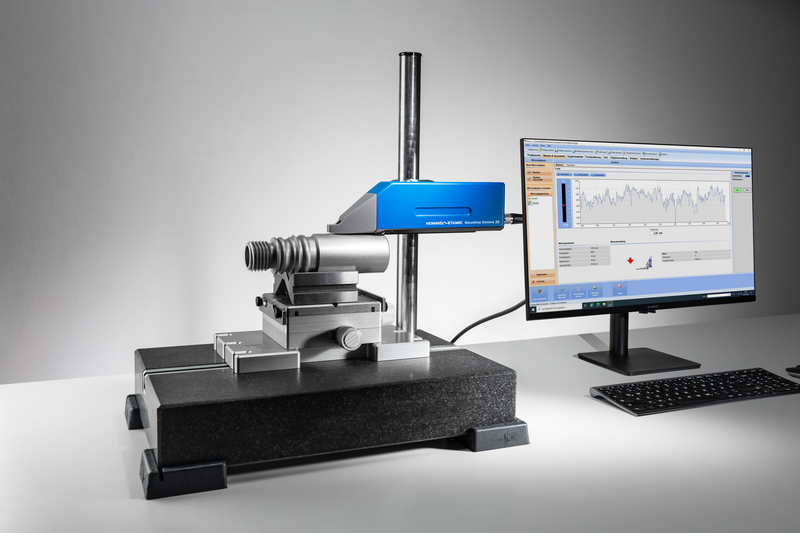

HOMMEL-ETAMIC WAVELINE W40

Manufacturer:

- JENOPTIK Industrial Metrology Germany (Germany)

Portable HOMMEL-ETAMIC WAVELINE W40 for measuring all common roughness, waviness and profile parameters.

The HOMMEL-ETAMIC WAVELINE W40 system, a new product of 2024, is part of a group of devices for mobile and stationary measurement of roughness, waviness and surface profile.

With its handy Waveline Xmove 20 traverse unit, the Waveline W40 set offers flexible options for measuring all common roughness, waviness and profile parameters. Operation is simple and intuitive thanks to the integrated start button and motorized probe lowering for automatic positioning of the probe.

The traverse unit masters measurements in all positions and orientations with ease - even overhead with the probes provided for this purpose. It can be optionally used in a compact measuring station or placed directly on a large workpiece for measurement.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features:

- Handy traverse unit for a wide range of diffrent measuring tasks;

- Integrated start button for one-handed operation;

- Optional, compact measuring station, can be used in the measuring room or in production;

- Solves all common roughness and waviness measurement tasks;

- Supports reference plane and skid probes;

- Motorized probe lowering for automatic positioning and positioning and lifting after measurement;

- Measurement in all positions and orientations, including upwards;

- Variable measuring speed;

- PC-based evaluation with Evovis Mobile Standard;

- All current standards including the new ISO 21920 series of standards;

- Flexible program design and logging;

- Export of characteristic values and profies, optional statistical interfaces;

- Large range of probes.

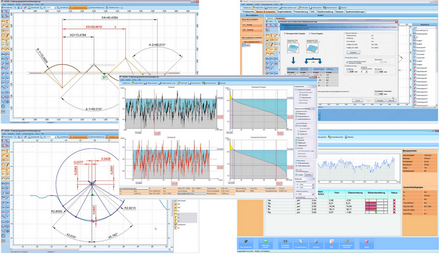

Software

The software is easy to use and offers a standardized interface for measuring roughness and contour, regardless of the configuration of the device. Simple icons are supported by integrated help function allows the user to use efficient tools of measurement and assessment in accordance with their own requirements.

Special abilities:

- Specially developed software for working with portable measuring devices;

- Online mode: management of W5, W10, W15 or W40 connected to the PC is performed directly by the software;

- Offline mode: the profile settings and data stored in the W5, W10 memory are transferred to the PC for further evaluation through software capabilities;

- Individual creation of a plan for testing;

- Master of the choice of measurement conditions;

- More than 90 parameters for estimating ripple and roughness in accordance with EN ISO 4287, as well as other ISO and national standards (ASME, DIN, JIS, Motif, etc.);

- Free print protocol design;

- Electronic archiving of measurement protocols in pdf format and automatic saving function.

Technical data

| Max. traverse length | 20 mm |

| Probe lowering | 4 mm |

| Guide accuracy | 0.2 µm/20 mm |

| Measurement speed | 0.2 – 2 mm/s |

| Positioning speed | 0.2 – 3 mm/s |

| Measuring range/resolution | ±300 µm/1 nm* |

| Interface | USB-C |

| Probe connection | TK probe (6-pin) |

| Internal alignment range | ±2° |

| Measurement position | Any position, also upwards** |

| * - across the entire measuring range | |

| ** - depending on the probe | |